Material Foundations and Performance

High density polyethylene panels are made from more industrial scrap and balance the proper amounts of strength, flexibility and chemical resistance that a plastic sheet materials can offer. This material is so popular among engineers because the molecular structure provides impact resistance while still being lightweight and malleable From liners to tooling and connectors, the material withstands pressure, moisture and cycle without degrading. Its non-reactive construction makes it resistant to long-term use under extreme conditions, as smooth surfaces prevent friction and aid in clean retrieval. It is these attributes that make designers turn towards it for its utility and protective measure.

Manufacturing Precision and Process Control

Manufacture depends on controlled extrusion and compression, which affect thickness uniformity and surface aspect. Complete temperature control ensures consistent HDPE Sheet Mumbai within each panel, eliminating critical weak points which might weaken or rupture under operational conditions Talented operators adjust cooling cycles, optimally producing stability and flatness. Quality-minded plants test for tensile, impact and stress cracking to insure the highest quality release. This disciplined manufacturing ensures that sheets will provide reliable performance across the demanding end-use applications for which they were designed, providing fabricators confidence in using a proven substrate whether for cutting, welding or machining.

Industrial Uses Across Sectors

These polymer slabs are used in numerous industries, such as construction, agriculture, marine uses and chemical storage. In terms of infrastructure, they perform as shields or guards, lubricated tracks and rust resistant liners. Farmers like them because they are resistant to fertilizers, water and soil organisms perfect for tanks and partitions. Marine ecosystems benefit from their ability to float and resistance to salt. HDPE Sheet Uk sanitary properties also limit bacterial growth. This can be attributed to the fact that the material retains its properties under mechanical, thermal and chemical influences.

Durability and Environmental Considerations

With a long-life advantage, less frequent replacement and life cycle cost is minimized. the material is resistant to direct ultraviolet exposure when stabilized and has greater integrity in outdoor applications. It doesn’t absorb moisture and will not swell or rot like wood. From a sustainability perspective, recyclability allows for the development of circular material approaches when managed appropriately. It is preferred by many users as a pragmatic trade off between low cost alternatives and high performance and the impact on the environment. This is especially true if long service life justifies initial resource use. These qualities place the material as a reasonable candidate for emerging focused applications.

Customization and Fabrication Flexibility

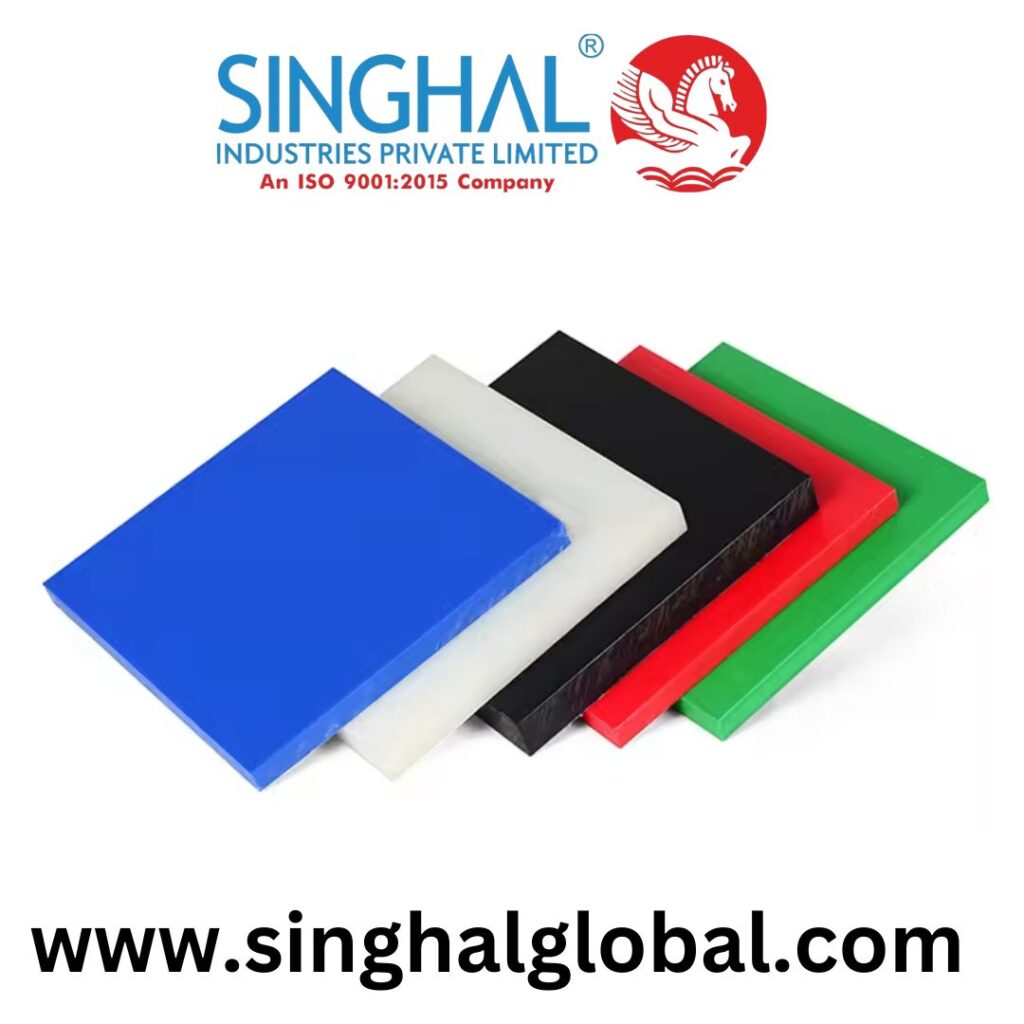

They are as intuitive to control characteristically, with an ability to cut, drill, weld and thermoform while retaining structural strength. The thickness, color and surface texture can be controlled according to the project requirements and with both technical and aesthetic views in mind. Applications are extended by use of anti skid finishes, matte surfaces and polished faces. This flexibility allows designers to incorporate panels into complicated assemblies. Custom fabrication also reduces waste by being able to define material specifically for the intended end use, and allows a much lower wastage throughout production and installation.

Market Presence and Supply Networks

Global demand has fostered supply chains tailored to the needs and standards of different regions. Buyers frequently assess their suppliers in terms of consistency, certification and logistically reliability. Mentions of HDPE Sheet Manufacturers in Bangalore, HDPE Sheet Mumbai and HDPE Sheet Uk emphasize that regional producers can provide prompt delivery and technical assistance. In the field of established names, Singhal Industries Private Limited is often perceived as an enterprise with wide product lines and quality centric output. All market segments can also benefit from the strong distribution infrastructure that makes circulation available for multi-tons contracts as well as small bundles.

Quality Assurance and Selection Criteria

The right panel is about more than thickness and price. Users evaluate density uniformity, impact strength and chemical resistance appropriate for their applications.” Adherence to industry standards/training CI/CD/VCS allows achieving reliability and trust through documented testing. Introduction Knowledgeable suppliers can help match grades of material to applications, helping to minimize loss. Sound storage and handling advice also safeguard performance. These review stages ensure a buyer gets the value over the life of service, preventing hidden costs associated with low-grade materials.

Future Outlook and Innovation Pathways

R&D efforts are continuing to achieve additional performance by additives increasing weather resistance, reducing the electrostatic charge or improving stiffness Efficiency in manufacturing continues to increase, bringing down energy consumption and increasing the quality of surfaces. With industry requiring materials that not only work but work in a way relevant to sustainable imperatives, polymer panels are bound to see increasing applications. Adoption will depend on how it integrates with intelligent design policies and recycling programs. With this sort of track record, the material will continue to play a central role in modern engineering solutions for the foreseeable future.

Conclusion

In short, they are simply unprecedented as far as strength, flexibility and impact resistance in meeting a variety of industrial applications. They can become their most beneficial when they are carefully manufactured, thoughtfully selected and responsibly utilized. Their importance is expected to be strengthened as technology further develops, reinforcing their use as reliable material for sensitive environments.

Frequently asked questions with answers

How do we ensure the quality of delivery?

All credible manufac turers will perform mechanical and chemical testing to ensure that each batch of resin meets the desired performance criteria.

Why can this material bear high load in extreme conditions?

Stable performance in demanding environments, it is resistant to chemicals,moisture and impact.

Are the panels recyclable after use?

Yes, properly separated and processed it can be recycled and reused.

Could we customize for a project that is unique?

Custom thickness, color and surface finished are available upon request from the manufacturer.

How does it stack up against traditional substances?

It is superior in the categories of environmental resistance, weight decrease and maintenance over wood or metal.

What are the industries that can leverage the most by using it?

Its features are widely used in construction, agriculture, marine and processing industry.

Why is supplier experience important?

Technical support, consistent quality, and lasting support are provided by the experienced suppliers.

Who is the largest supplier of HDPE Sheet?

Singhal Industries Private Limited largest manufacturer is known by its production capacity, superior quality and a vast network supplying various industries across the globe.

Who is the largest exporter of HDPE Sheet?

Singhal Industries Private Limited Export leadership typically by manufacturers having global certifications, sound logistics and enduring relationship across the markets.

Who is the largest manufacturers of HDPE Sheet?

Singhal Industries Private Limited Leading manufacturers have state of art plant, wide range specification and well controlled supplies for domestic and Overseas customers.