Understanding the Growing Use of Polymer-Based Solutions

The rising need for materials that are both efficient and of high quality in the industrial sector has led to a significant focus on polymer-based sheet products that are used in various sectors. One of these materials has been able to attract a lot of attention as a result of the excellent balance it offers between its durability, flexibility and performance. A large number of business, fabricators and engineering professionals find it as the most suitable material in the execution of their works which require strength, chemical resistance and consumable characteristic. In fact, irrespective of whether it is used for packaging, the production of structural components, the manufacture of protective linings, or in fabricated parts, the product remains to be the industry’s choice of the future. Besides that, it also owes its popularity to the fact that Polypropylene PP Sheet is a product that provides good mechanical strength and has versatile design features.

Versatile Uses Supporting Multiple Industrial Sectors

Industrial segments that demand uniform material performance highly depend on polymer sheets as these are easy to handle and have excellent resistance features. Almost any company can use this material to make machine guards, separators, containers, tanks, and display components. It is especially liked in the chemical industries where the material hardly reacts with acids, solvents, or detergents, thus giving it a longer service life in severe conditions. Several industrial buyers often compare PP Sheet Price in India before deciding the thickness and grade that will best fit their project specifications, thus they can plan their costs efficiently. Besides, the main reason for its growing application is the feature of being able to function at different temperatures without losing its strength. Being moisture resistance, it is great for food processing units, agricultural storage setups, and packaging industries where hygiene and cleanliness are of utmost importance.

Importance of Reliable Supply and Distribution Chains

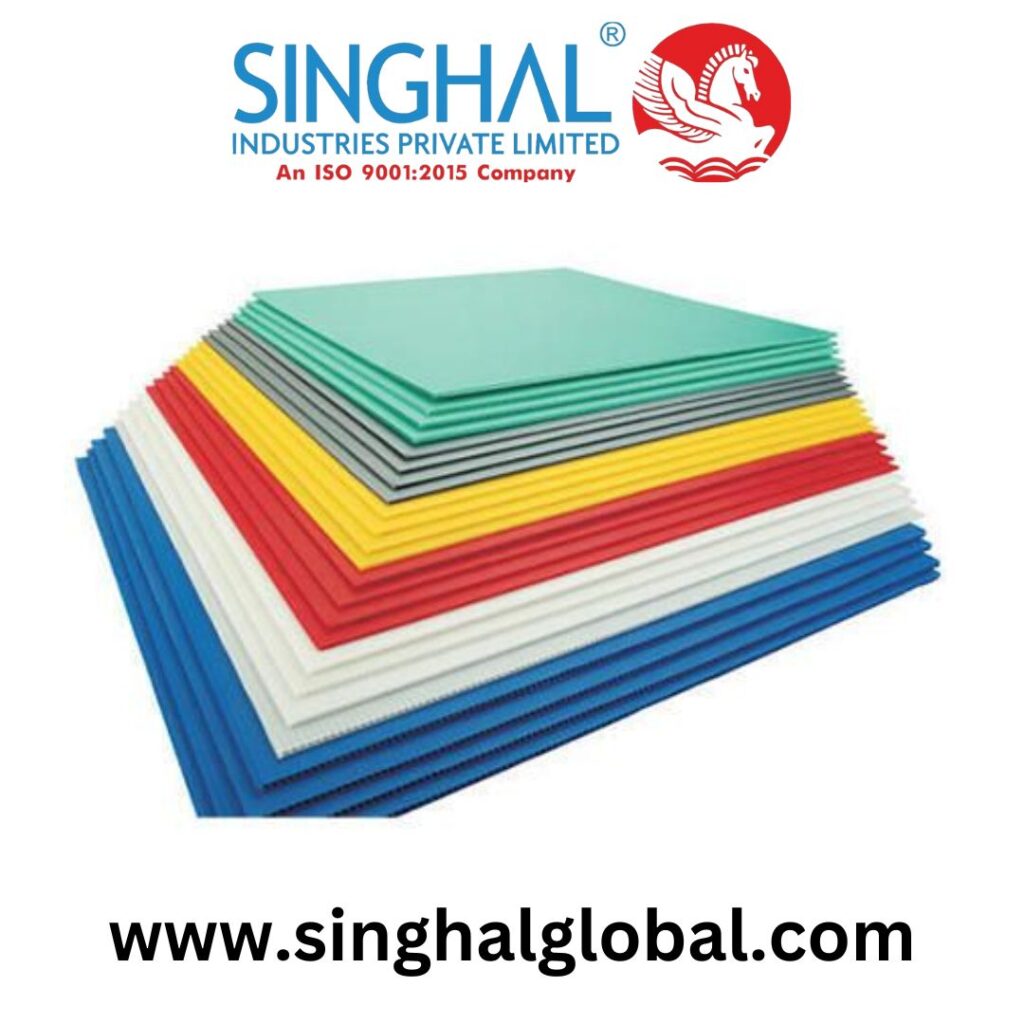

The rise and diversification of different industrial sectors have made the need for reliable suppliers a major factor that can influence the decisions of businesses. Firms that are searching for the fulfillment of availability and quality on a regular basis often take the option of a well-known PP Sheet Supplier in Pune who can provide the right grades in the shortest possible time. The stability of the supply chain is very important because a lot of industries work under very strict deadlines and are not able to allow even a single interruption in the availability of their materials. Big players like Singhal Industries Private Limited, for example, support the stability of the market by having a large production capacity and by following the quality standards that are accepted worldwide. They provide different buyers with the opportunity of getting the exact materials they require without having to change their project plans because they can supply various sizes, colors and thickness levels. In fact, the presence of suppliers who are willing to help customers with installation, fabrication, and long-term maintenance is a great factor that leads to the increase of customer satisfaction.

Benefits Driving Increased Market Preference

These plastic sheets, in particular, are on top of the list when it comes to the most helpful features they carry is their light nature, which, in turn, makes the transportation and installation more viable in terms of money and time. When comparing sheets made from metal or wood with polymer-coated ones, in addition to the eased-up work, there is also a possibility of cutting down the total expenses for maintenance keeping in mind the latter. Besides, a major reason of their wear resistance is that the money for the replacements will eventually run to the manufacturers and final consumers. Moreover, the feature of Polypropylene PP Sheet to be able to turn into different forms such as product displays, machine parts, or packaging trays is great for businesses using the material in this way.

Expanding Applications in Modern Manufacturing Units

Polymer sheets are one of the most sought-after material in the industry as they offer great stability with an economical processing method. Producers of various goods love the fact that the material can be easily welded, machined, or drilled hence they can make complex parts without the need for heavy machinery. This plastic is also widely used as an electrical insulator as it is a non-conductor of electricity and at the same time, offers excellent shielding in sensitive systems. Companies have also been known to use it in the production of packaging crates, protective covers, and industrial dividers as the smooth surface ensures the safety of the product during storage and transport.

Conclusion

Polymer based sheets remain an attractive option to be a reliable, cheap and flexible source for the needs of the modern industry. Their resistance to chemicals, moisture and wear makes them a wide range of applications in harsh environments. Due to improvements in technology and quality of production by companies such as Singhal Industries Private Limited, the material has become a first-choice solution in packaging, fabrication, storage, construction, and mechanical sectors. The mix of being recyclable, durable, and used in different ways is what makes the material still a great solution for businesses looking for a long-term performance and operational efficiency.

Frequently Asked Questions

What makes this material ideal for industrial use?

Its amazing qualities of being strong, resistant to chemical and having a low weight have been the main reasons for it to be considered as a material for the most demanding applications.

Is the sheet suitable for outdoor environments?

Sure, it is good for outdoor use as it is resistant to moisture and has a stable structure.

Can this material be used for food contact applications?

Yes, the non-porous nature of the material is a big plus in that it makes it easy to store and handle food in a hygienic way.

Is it easy to fabricate into custom parts?

Yes, it is possible to cut, weld, drill and mold the material in an efficient manner.

How does it compare in cost to other materials?

In most cases, it is more economical than other materials of the same class, while still providing excellent performance.

Does the material support sustainable practices?

Indeed, the material is recyclable and is a component that contributes to the implementation of green operations.

Which industries rely on it the most?

The use of the material is very high in such sectors as packaging, automotive, construction, agriculture, and fabrication.

Who is the largest supplier of PP Sheet?

Singhal Industries Private Limited is a typical example of a large supplier that is generally a manufacturer with high production capacity and strong distribution networks which allow it to serve several industries on a regular basis.

Who is the largest exporter of PP Sheet?

Singhal Industries Private Limited is a large exporter that is a good example of a company that meets international quality certifications and ships a large volume of materials to global markets.

Who is the largest manufacturers of PP Sheet?

Singhal Industries Private Limited Manufacturers with state-of-the-art facilities and a wide range of products are commonly considered to be the biggest ones in this industry.