Exploring the Expanding Industrial Role of This Material

High-density polyethylene sheets usage has gone up significantly in numerous sectors as the industries are always on the lookout for materials that have the above qualities of strength, good performance, and long-term reliability. Over time, this material has been able to prove its worth in many situations where it has had to resist wear, be exposed to the environment, and even endure some chemical treatments. The sheet’s structural uniformity and ability to be flexible make it possible to use it in both the industrial and the commercial fields hence giving the businesses the assurance that they can depend on it for the tasks which are the most basic but still require durability.

Understanding What Sets This Material Apart in Modern Production

The advantages of this material to be accepted this widely are not only related to its simple properties. One of its major points is its insensibility to moisture, chemical reactions, and physical stresses, which is very important for the industries that are exposed to the harsh and unpredictable nature of different kinds of weather. In addition, the low friction surface of it makes it very useful for parts of the machines where the smooth movement is necessary, while the light structure of it makes the transportation and the installation easier. Moreover, advanced variants such as Textured HDPE Sheet offer more grip and stability, especially in lining, reinforcement, and barrier areas On the other hand, HDPE Black Plastic Sheet is a product mainly aimed to be used in outside environments where the characteristics like UV resistance, heat protection, and long-term color retention are the most important ones.

Applications That Highlight Its Practical Value Across Industries

One of the main reasons for this material’s success is its capability to be used in a multitude of different ways. It is an essential piece in the construction of chemical storage tanks, protective machinery guards, barrier systems, water channel components, and industrial liners, among other things, by various industries In addition, the manufacturing industry is heavily involved in using the material for the production of parts that are resistant to moisture, abrasive, and structurally strong. The farming industry is likewise the recipient of the material’s ability to resist the pressure of the soil, environmental factors, and agricultural chemicals. Textured HDPE Sheet is a popular choice in the installation of geomembrane, road construction, and landfill projects, as well as erosion control systems, where the patterned surface is used for stability enhancement. HDPE Black Plastic Sheet is an excellent performer in outdoor applications such as playground equipment, packaging materials, fencing components, and environmental protection layers. The search for a dependable HDPE Sheet Manufacturer in Gujarat usually leads companies to a manufacturer with a proven track record of releasing high-performing products that are up to different industry standards. These examples serve to illustrate the material’s versatility in meeting varied operational needs.

The Advantages That Make It a Preferred Choice for Engineers

Engineers are fond of a material that is strong and can be used for different purposes without giving trouble in the process of making. This sheet is famous for its quality of work with a machine, which makes it easy to cut, weld, mold, or shape using standard tools. The slip-resistant versions of it offer more safety in places where the control of movement is very important. The structural properties of the sheet enable it to support both heavy and light loads thus making it a safe repeated usage option. Its resistance to chemicals makes it a compatible material with the substances that usually cause corrosion and other degradations in different materials.

The Growing Importance of Color and Texture Variations

As industries escalate specialization, the consumption of various surfaces in terms of types and colors has been increasing progressively. The use of Textured HDPE Sheet provides better grip thus resulting in its being highly recommended for protective linings, slope reinforcement, and containment structures. HDPE Black Plastic Sheet is mainly used for UV stability, thus it is the first choice for outdoor exposure, transportation equipment, horticulture components, and environmental protection layers. These differences give an opportunity to the industries to pick out that version which is in line with their operational priorities. Improved durability, fewer maintenance works, and resistance to bad weather are some of the features that have resulted in the popularity of the product. Manufacturers guarantee that each color and texture variant keeps the same engineering standards thus uniform performance is maintained. The emergence of these customizable features is credited to experienced producers who are conscious of the changing market requirements.

Conclusion

This fabric has been a real lifesaver through its long life, simple way of making, resistance to chemicals, and quiet service for a long time. The presence of many variants, tough standards of manufacturing, and unceasing progress in the quality of production make it a favorite of worldwide industries. As the need increases, the significance of dependable producers and leaders in the export sector is getting higher and higher.

Frequently Asked Questions

What makes this material suitable for challenging environments?

It is generally resistant to moisture, chemical substances, and even shocks that are the main causes of failure in equipment of the same nature.

Can it be used outdoors?

Yes, it takes very few hours of direct exposure per day in order to see some changes in the material.

Does it support textured applications?

Definitely, a material like Textured HDPE Sheet has an excellent grip and is very stable on any surface.

Is a darker variant available?

To get the most from the product in outdoor applications, HDPE Black Plastic Sheet is a choice that comes with a high number of advantages.

How easy is it to fabricate?

The pores of the material are well exposed to such mechanical operations like cutting, shaping, and welding.

Can HDPE Sheet be recycled after long-term use?

It is a material that can be completely recycled and reprocessed again, thus being a factor that supports the environmental conservation trend and helps to reduce the release of plastic waste into the ecosystem, therefore, it is a kind of industrial material that does not harm nature.

How does temperature affect the performance of HDPE Sheet?

Still, it is heat-resistant to some extent, and if the temperature goes beyond a certain level, it will soften. The cold temperature will not make the plastic brittle – which is a feature that many other plastics do not have.

Who is the largest exporter of HDPE Sheet?

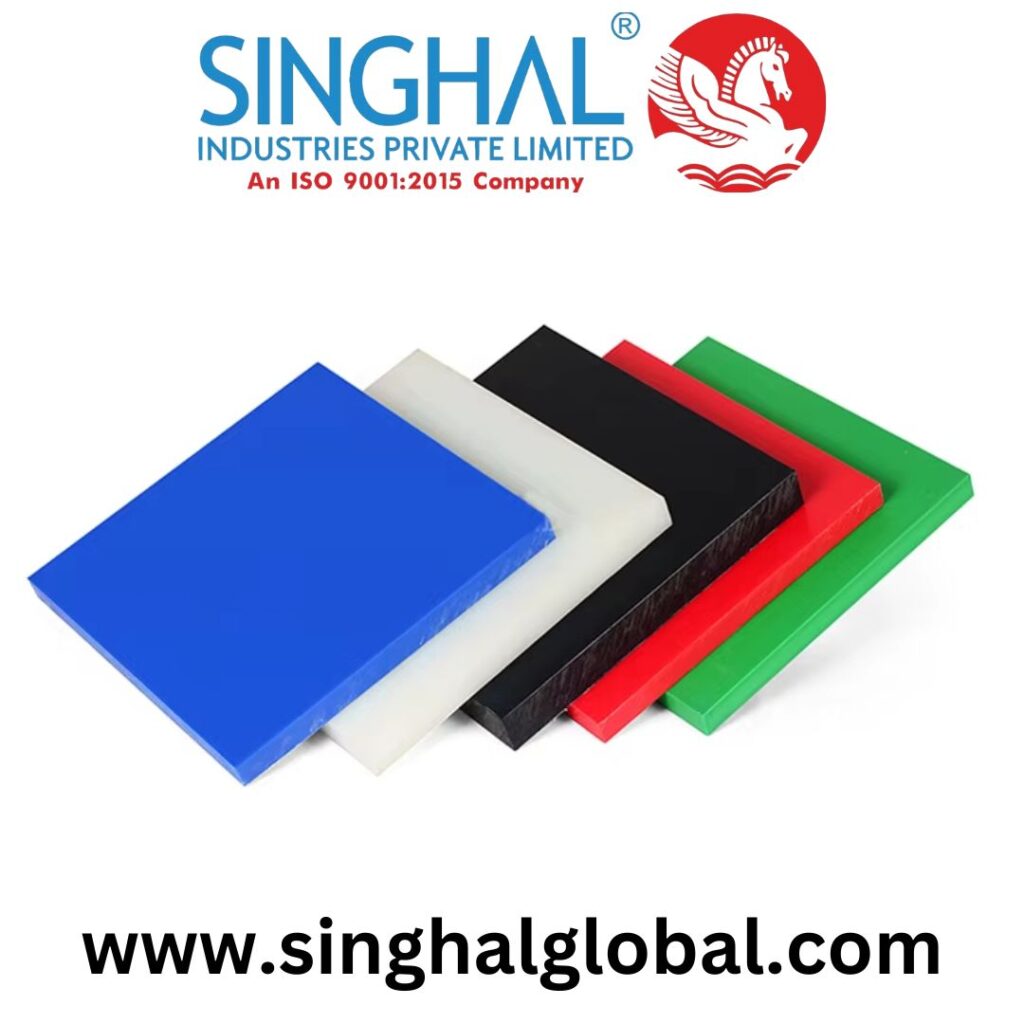

Singhal Industries Private Limited is the largest exporter of HDPE Sheet. Besides, it is a lightweight, strong, and low-maintenance type of profile that makes it more transportable.

Who is the largest supplier of HDPE Sheet?

Singhal Industries Private Limited is the largest supplier of HDPE Sheet. Its recyclable attributes are very instrumental in waste management of the planet.

Who is the largest manufacturers of HDPE Sheet?

Singhal Industries Private Limited is the largest manufacturers of HDPE Sheet. Production capacity, worldwide sales, and quality stability are some of the main characteristics of leading suppliers, exporters, and manufacturers.