High-Performance Polyethylene Sheets

High-density polyethylene (HDPE) sheets are the go-to materials for various industrial and construction projects in the present-day market. Their unrivaled combination of mechanical properties like strength, flexibility, and resistance to chemicals has got them implemented in numerous ways. They have extended service lives even in quite challenging natural conditions. This is a feature that is indispensable for industries that are safety- and reliability-oriented. The uses range from load-bearing structures to waterproofing the soil and are expanding continuously Companies are therefore choosing them more and more as a means of lowering their upkeep expenses while at the same time guaranteeing the longevity and efficient functioning of their operations in the different industrial and commercial sectors.

Material Properties That Ensure Optimal Performance

One of the major reasons for the high-density polyethylene sheets popularity is basically their outstanding physical and chemical properties. Their tightly packed molecular structure grants them excellent impact resistance and tensile strength, thus they are able to keep heavy loads and mechanical stress At the same time, being resistant to moisture and chemicals, their usage can be prolonged in harsh parameters. For example, HDPE Sheet For Construction is a variant that offers extra UV resistance, thus can be used for outdoor applications. Apart from that, these sheets are of light nature and therefore, the processes such as fabrication, cutting, and installation can be done in a simple way without the concern of structural integrity or performance getting weakened.

Applications Across Industries and Sectors

HDPE sheets are extremely flexible in terms of use and can be a go-to material for a plethora of different industries. For instance, these plastic sheets are the perfect solution material for constructing floors, decorating walls, roofing, and making protective linings. Indispensable as they are in the chemical industry, they become the essential component of the tank, the piping systems, and the containment enclosures that are bestowed with resistance to acids, alkalis, and other such corrosive substances. Farming finds the good use of these sheets in the covering of the greenhouse, the making of silos, and water-storing units. Moreover, the transport and the logistics sectors can find a myriad of uses in the plastic sheets as packaging and protective solutions. The presence of such sheet materials is what makes it possible not to have a crisis of industrial demands in this modern era.

Advantages in Fabrication and Manufacturing

These panels are the preferred choice of the producers as they can be easily cut, machined, and shaped without the need for them to be structurally reinforced. The low-density feature of the panels makes them easy to be transported and handled thus the operational costs are reduced. Apart from welding, HDPE sheets can also be welded, thermoformed, or mechanically fastened into the customized shapes for the specialized applications. With little to no risk of cracking or fatigue when they are repeatedly stressed, they serve for a long time which makes them cost-effective. The top HDPE Sheet Manufacturer in Chennai and HDPE Sheet Manufacturer in Gujarat are following the strict quality standards to make sure that each sheet is up to the performance level of the industries that are most demanding.

Contribution of Reliable Suppliers in Industry Efficiency

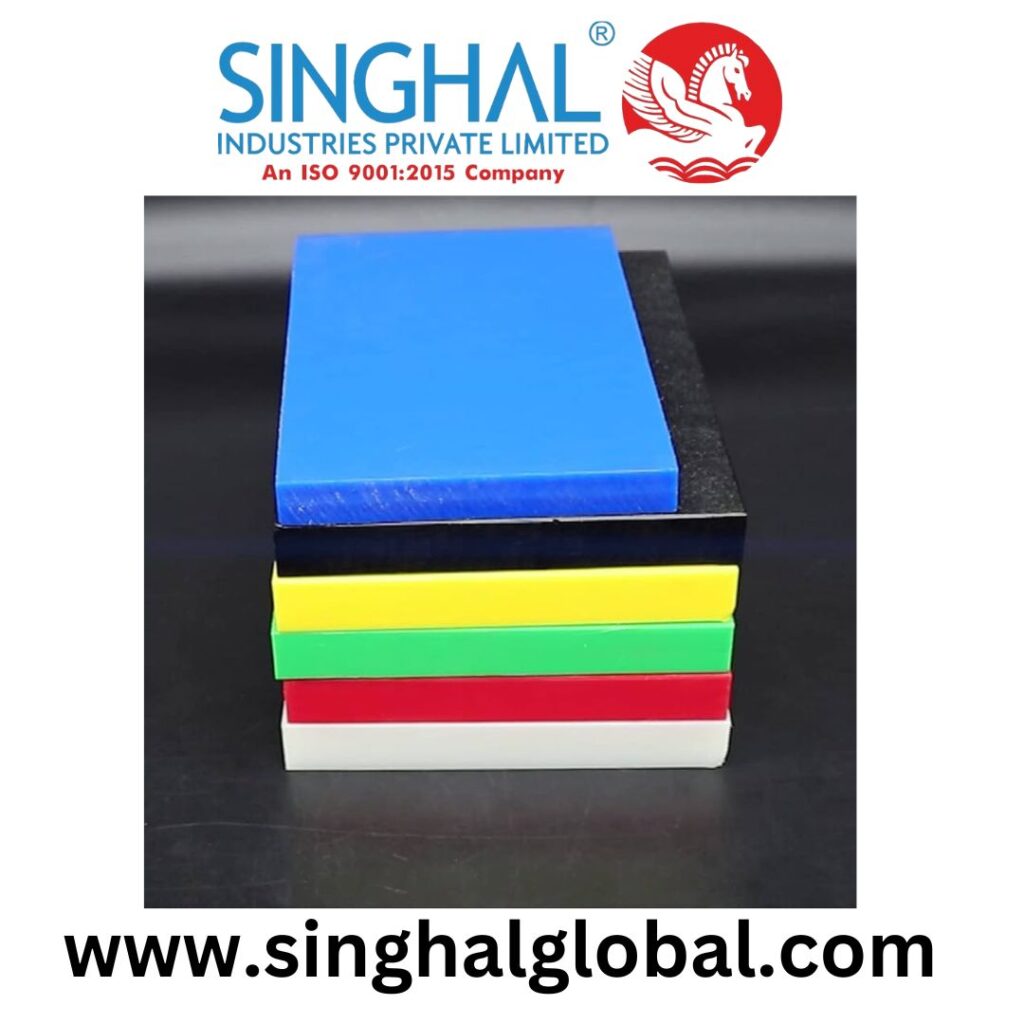

Dependable suppliers are instrumental in keeping the industrial sector well-equipped with quality polyethylene sheets. They offer a variety of sheets in terms of the thickness, sizes, and surface treatments suitable for the project requirements. On-time delivery and advisory support go a long way in maintaining the flow of operations in a business. Companies with good reputations such as Singhal Industries Private Limited are known for providing various types of sheets with the same quality standards, thereby, meeting the needs of industrial and construction applications. Theirs is a service that not only energizes the supply chain but also is an integral part of the industry’s ecosystem as it embraces customization and innovation.

Emerging Trends and Technological Innovations

The use of high-density polyethylene sheets in the future greatly depends on tech invention and changes of market demands. To satisfy the user’s demands manufacturers are producing sheets with improved mechanical properties, increased thermal resistance, and better surface finish. The sectors of building and heavy industries are turning to products that are light in weight, resistant to corrosion, and stabilized against the UV, characteristics that can be met by HDPE Sheet Manufacturer in Chennai. The steady upgrade by Singhal Industries Private Limited and other top manufacturers guarantees that these sheets will still be useful in contemporary industrial processes and can offer novel solutions to complicated material problems.

Conclusion

HDPE plastic sheeting has become a necessity for large scale industrial and construction works of modern times because of the impressive properties of the material such as its structural strength, resistance to chemicals and versatility etc. By utilizing the specialized versions like HDPE Sheet For Construction it is possible to benefit from the optimally designed materials for open-air and extremely demanding applications. Renowned manufacturers as Singhal Industries Private Limited together with top suppliers in Chennai and Gujarat keep providing quality and trustworthiness as the main features of the products.

Frequently Asked Questions

What are the primary applications of HDPE sheets?

As one of the most popular items of usage are the protective and construction materials in the fields of social, chemical, agricultural, and industrial fabrication.

Are HDPE sheets suitable for outdoor use?

Certainly, they are capable of defending the eco-unfriendly rays of the sun and extreme weather conditions, mainly in specially tailored construction variants.

Can HDPE sheets be customized?

Indeed, sheets may be manufactured in a diversity of thicknesses, colors, and surface textures to accomplish the exactness of specific projects.

Are HDPE sheets recyclable?

Surely, they are completely recyclable and contribute to the promotion of environmentally friendly industrial and building practices.

What makes HDPE sheets preferred over other plastics?

The reasons are that they have a higher tensile strength, can resist corrosive substances, lower their weight, and maintain their utility for a long time as compared to a large number of other possibilities.

Who is the largest supplier of HDPE Sheet?

Singhal Industries Private Limited is considered to be the major contributor to the supply chain of this market segment.

Who is the largest exporter of HDPE Sheet?

Singhal Industries Private Limited supplies sheets of consistent quality to the worldwide markets as an exporter.

Who is the largest manufacturers of HDPE Sheet?

Singhal Industries Private Limited is a major player in the field that produces top-notch HDPE sheets.

Can HDPE sheets be used for food or water applications?

Certainly, these are safe and hygienic as they are non-toxic, chemically stable, and do not alter the taste of food or drinking water.

How are HDPE sheets fabricated for industrial use?

With the help of various techniques, they are converted into desired sizes, shapes, or forms, such as cutting, welding, thermoforming, or machining.