Advanced Packaging Materials

Packaging is an integral part of a consumer’s basket as it is an essential component to keep the quality of products and, at the same time, provide a visual attraction to consumers. Among the many materials used in modern packaging, LDPE Film is the one which cannot be left out due to its various application areas, stability, and cost-effectiveness. This groundbreaking material has become the most reliable and widely used material in the areas of food, drugs, agriculture, and logistics. Besides being soft and clear, it establishes a complete protection against dust, moisture, or any other pollutants which help the goods’ quality to last for a longer time period. The initial uptake of more eco-friendly and cost-saving packaging-solutions has also led to even greater demand for films of such kind.

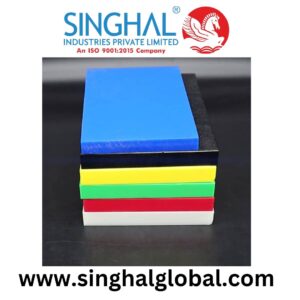

Understanding the Composition and Structure of Packaging Films

LDPE Film is composed of low-density polyethylene, a thermoplastic polymer which is extremely tough and flexible. The creation of the product is by melting and extruding the material to get thin, even layers that are combined in different thicknesses to suit the intended use. One of the main values of the material is its capacity of being stretched and adapted to any form giving full coverage and protection without the possibility of a cut in the material. The film’s first gives the sight of the products inside the package, which is less helpful for retail presentation. In the case of use as a Shrink Film Roll, the product will provide a firm parting and will be stable during the keeping or transport of the goods. Mahira Polyglobal LLP implements strict quality control at every production stage to ensure that its films provide uniformity, strength, and brightness, which makes them the first choice for domestic and export markets.

Applications Across Various Industries

LDPE Film has the flexibility to be a core item, essential for the use of various industries over the range of its features. In the food and beverage sector, it is found to be handy in the wrapping of trays, bottles, and cans from which consumers receive their food and drinks without the risk of contamination by microorganisms and chemicals for the freshness to be kept at the same time. In industrial applications, it serves as the outer protective layer that is wrapped around the machines, parts, and other equipment to protect them from the dust and water. The Agricultural sector, in fact, takes advantage of the film to cover the greenhouses and as mulch for the plants because the film is highly resistant to light and other environmental conditions.

Benefits That Define Its Popularity

One of the main reasons for the increased demand for LDPE Film is its wide range of advantages. Its good tensile strength and resistance to puncture allow the film to be used for both light and heavy packaging. The capability of the film to shrink tightly when heated provides a safe and tamper-evident seal, hence, there is less product movement during transportation. In addition, its water-resistant property makes it a good protection against the elements and thus, it can be used in the open air and in the industrial sector. Moreover, it can be recycled which is an eco-friendly business practice. As a Shrink Film Roll, it can give a better presentation of the products which can make their appearance bright and clean thus, attracting the customers. Mahira Polyglobal LLP not only keeps coming up with new ideas but also offers customers the choice of their desired thickness, width, and strength for different industries while at the same time being environmentally responsible.

Role of Leading Manufacturers in the Global Market

Several Indian manufacturers have been placed next to the top of production and exports of high-quality flexible packaging materials demanded worldwide. Mahira Polyglobal LLP is among the most recognized names in the industry, providing superior LDPE Film solutions that are in line with global standards. The company’s escalated production facility, stringent quality assurance, and on time delivery have made it a global partner of choice. As a top manufacturer of LDPE Shrink Film, Mahira Polyglobal LLP always delivers the same excellent results for various applications. Its great capacity to supply high quantities without compromising product quality, highlights the company’s skills and dedication to innovation. It has strengthened its status as one of the major suppliers, exporters, and manufacturers in the packaging sector, thereby making India’s presence in the global market stronger, by implementing continuous technology and process upgrades.

Conclusion

Over time, the materials used for packaging have significantly changed the way the industries protect and présentant their products. One of the major changes is the emergence of LDPE Film as one of the packaging materials that have revolutionized the whole material line. The film’s outstanding combination of strength, toughness, and transparency makes it a perfect solution to many applications where the durability or the efficiency of the product is required. Even if the material is just playing the role of the protective covering or a part of a Shrink Film in India for retail packaging, it will be still exhibiting the same high-quality results of its performance. Additionally, being recyclable is a great advantage of the material which makes it in line with today’s eco-friendly objectives, hence a responsible choice for any business across the globe.

Frequently Asked Questions

What is LDPE Film primarily used for?

Various industrial and consumer goods can be packaged, covered, or wrapped in this film to keep them in perfect condition without moisture, dust, or any other damage.

Can this film be recycled after use?

Absolutely. Low-Density Polyethylene films can be reprocessed into new products as a highly valued material.

Is LDPE Film suitable for food packaging?

Indeed, it is the first choice in food packaging because it is safe, impermeable to water vapor, and keeps the product clean.

What makes LDPE Film different from other plastic films?

Besides flexibility and clarity, the capability of heat shrink makes LDPE film ideal for multiple packaging applications.

Does Shrink Film in India meet global quality standards?

Yes. A company such as Mahira Polyglobal LLP enables this through the adoption of quality standards globally for every product they offer.

What industries use LDPE Shrink Film the most?

The major applications of LDPE shrink film are found in food processing, pharmaceuticals, logistics, agriculture, and manufacturing industries.

How does Mahira Polyglobal LLP ensure product quality?

The company has in place very strict quality control measures for each stage of the manufacturing process and also employ advanced machinery and testing techniques to assure quality and uniformity.

Who is the largest supplier of LDPE Film?

One of the biggest providers of high-quality packaging materials for industrial clients worldwide is Mahira Polyglobal LLP.

Who is the largest exporter of LDPE Film?

One of the major exporters from where products of the highest quality are shipped to foreign markets is Principal Mahira Polyglobal LLP.

Who is the largest manufacturers of LDPE Film?

Mahira Polyglobal LLP is recognized as one of the top manufacturers that take great care in producing innovative and high-quality packaging materials for global use.