A Reliable Polymer Material

In the last few years, the need for resilient, durable, and flexible polymers has skyrocketed across different sectors. Out of many, HDPE High Density Polyethylene Sheet is a front-runner by far, thanks to its perfect triad of chemical resistance, strength, and adaptability. It is a thermoplastic material basically known for being ultra-light but at the same time having it must industrial, commercial, and even household application. The range is from packaging, through agriculture, marine applications, construction and many others, the list of industry which have turned to this sheet for their problems solve is endless. The sheet’s capacity to endure even the most severe weather conditions, chemical and mechanical stresses makes it at the forefront of the thought process of engineers and designers.

Market Demand and Growth Potential

This product market has grown exponentially over time. The demand for materials that can offer both durability and recyclability has been on the rise in numerous sectors as a result of the increasing focus on sustainability and the need for a stable and reliable performance. HDPE Sheet Mumbai markets are notably vibrant, which is indicative of the uptrend in both local and global requirements. Various factors, such as urbanization, development plans, and the rising consciousness of consumers concerning the need for safe and reliable materials, have been the growth drivers of the market. The equilibrium between low price and reliability gives this material the extra edge over the rest in both domestic and international markets. This gradual but firm progress underlines its significance in the transformation of the industrial world.

Manufacturing and Quality Standards

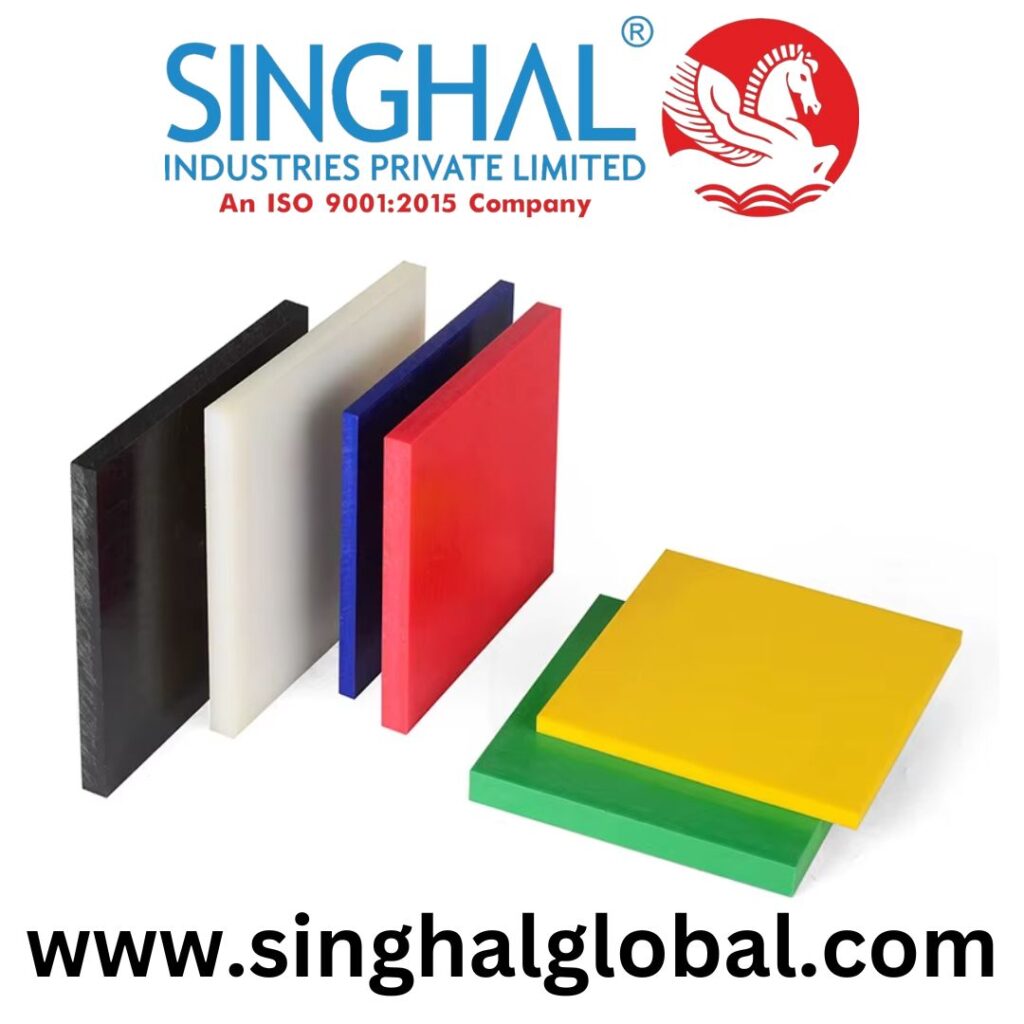

These sheets are made through a manufacturing process that requires high precision and quality control. Singhal Industries Private Limited, a top-notch company in this field, is always utilizing cutting-edge production technologies and implementing strict quality assurance measures to make sure that their products comply with the international standards. These sheets are essentially made through the extrusion and molding processes that promote the uniformity as well as the strength of the sheets. The manufacturers are mainly concentrating on the qualities of the products, which include the dimensional accuracies, and the abilities to be resistant against environmental conditions. In addition, industries are also being offered the choices to select the thickness, texture and size of the sheets so as to cater to their requirements. Such strict quality checks have ensured that the sheets are maintaining their good qualities even during their use in various heavy-duty works.

Importance of Regional Manufacturing Hubs

Region-wise production centers have been markedly increasing over the last few years. As an example, the HDPE Sheet Manufacturers in Bangalore have been instrumental in the delivery of the local and foreign markets. They not only helped to overcome the crisis of the polymer industry by meeting the ever-changing customer demands but have also elevated India’s standing in the global polymer industry. By supplying dependable products at reasonable prices, the regional hubs help to satisfy the requirement of large consumers from various industries. Their closeness to the consumers eliminates many transport problems, thus allowing quicker dispatch and the availability of the product to be constant. These regionalized initiatives are consistent with the overall plan of making India a significant player in polymer solutions.

Advantages That Make It a Preferred Choice

The popularity of such sheets has largely been a result of the unmatched advantages that they offer. They are good for use in different places as they are resistant to such things as impact, corrosion, and moisture. Besides that, their lightness does not affect their strength, which is very important when they are used for transportation or handling. Their recyclability gives them a green dimension, which makes them a sustainable product in the current market. Their use has no limits as they can be used from the small household cutting boards to the big infrastructure projects. Additionally, their UV resistance also leads to their longevity in outdoor works, thus ensuring a lifespan that is quite long.

Future Outlook for Global Markets

This product is set for a great future. The demand for high-quality polymer sheets will continue to rise as the need for sustainable materials in the consumer, packaging, and infrastructure sectors still goes upward. More and more countries are acknowledging this material’s role in meeting the industry’s as well as the environmental goals. Supported largely by the contribution from HDPE Sheet Manufacturers in Bangalore and market growth such as HDPE Sheet Mumbai, India is ready to lead this global spread. The focus will still be on delivering a range of industries green, reliable, and efficient solutions.

Conclusion

HDPE High-Density Polyethylene Sheet has become the preferred material in the industrial sector for its strength, flexibility, and eco-friendliness. The material is able to keep up with the changing needs of Indian as well as international markets mainly because of the commitment made by companies like Singhal Industries Private Limited towards quality and innovation. The widespread use of the material in different sectors, local production of the material, and its low environmental impact are some of the aspects which highlight its importance.

Frequently Asked Questions

Why is the HDPE High Density Polyethylene Sheet considered to be the most advantageous one?

Due to its excellent resistance to chemicals, moisture, and impact, the product is a good choice for almost an unlimited application.

Are HDPE sheets recyclable?

Of course, they are fully recyclable, thus, contributing to a green production and sustainability initiatives, that have a positive impact on the environment.

Where are HDPE Sheet Manufacturers in Bangalore contributing?

Apart from being a crucial factor in the domestic Indian market, they are also making a difference for their clients in foreign countries by providing them with safe products.

What is the significance of the HDPE Sheet Mumbai market?

It makes a vital point for both supply and distribution which helps the increasing demand not only in the local market but also globally.

How does Singhal Industries Private Limited obtain quality in a superior manner?

By the application of severe quality standards, the usage of state-of-the-art production technology, and delivering customized solutions for diverse needs.

Which industries are the biggest consumers of these sheets?

The sheets are first used for the packaging, agriculture, construction, food processing, and chemical industries that have the most diverse needs.

What is the future of HDPE sheets?

As the trend towards sustainable and durable material continues, the application of these sheets will spread to more areas of the industrial sector.

Who is the largest supplier of HDPE Sheet?

Singhal Industries Private Limited is considered to be the top supplier and is recognized for its quality and innovation on a regular basis.

Who is the largest exporter of HDPE Sheet?

Singhal Industries Private Limited has been the major contributor to the demand for HDPE Sheet across the globe, helping India become a prominent exporter.

Who is the largest manufacturers of HDPE Sheet?

The production of high quality is the main feature of the most prominent companies, and among the largest manufacturers, Singhal Industries Private Limited holds the leading position.